The Three-Dimensional Bin Packing Problem (3D-BPP) is crucial in modern industrial and logistics systems. With the total social logistics costs reaching 18.2 trillion RMB, accounting for one-seventh of the Gross Domestic Product (GDP), the logistics industry has become a key sector in the national economy. Packaging is a core aspect of logistics, and effective 3D bin packing strategies can maximize transportation space utilization, reduce shipping costs, and ensure the stability and safety of goods. Under the framework of Industry 4.0, the use of robotic arms for 3D bin packing is becoming increasingly prevalent. Effective coordination of robotic arms in packing processes can enhance automation and intelligence in the packaging industry, reduce packaging material waste, and promote environmental sustainability.

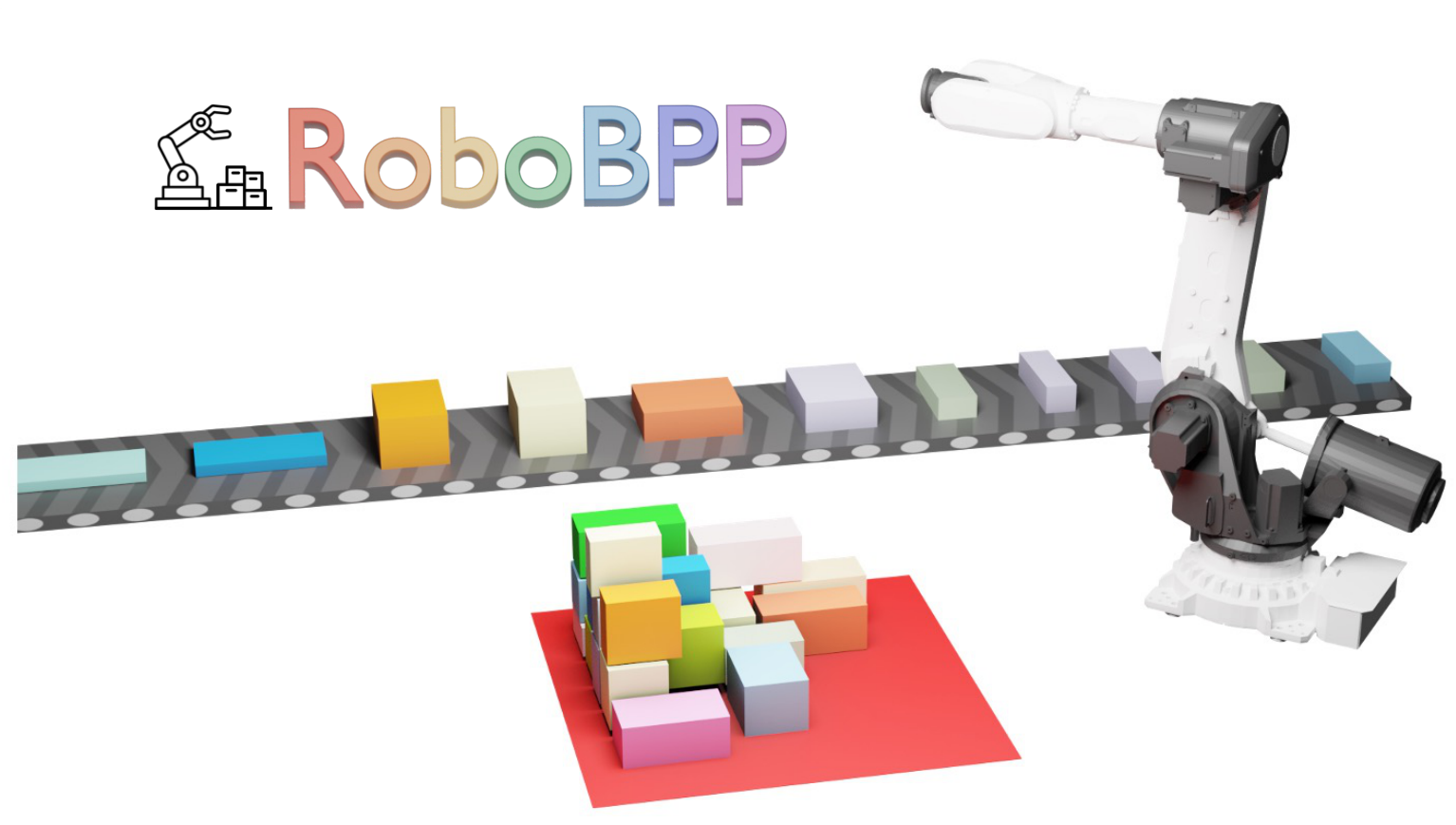

Despite these advances, current research still suffers from several fundamental limitations. Existing methods are evaluated under inconsistent problem formulations, heterogeneous datasets, and incomparable metrics, while many state-of-the-art approaches remain closed-source, limiting reproducibility. Most works further treat online 3D-BPP as an abstract optimization problem and ignore physical constraints such as gravity, friction, and dynamic stability, making their conclusions difficult to transfer to real robotic systems. In addition, the heavy reliance on synthetic data leads to distributional gaps from real industrial workflows, raising concerns about practical validity. These issues collectively prevent fair comparison and hinder progress toward deployable packing solutions. To overcome these limitations, we introduce RoboBPP, a unified benchmarking system that standardizes evaluation through real industrial datasets, physics-based simulation, and robot-aware metrics.

This work makes the following major contributions:

From left to right, the three videos below show the simulation effects of the bin packing problem on three real industrial datasets under three test setting.